Ever picked up a riveting tool and wondered how it works? You’re not alone.

Understanding the mechanics behind this handy device can transform your DIY projects and elevate your craftsmanship. Imagine building or repairing something with the confidence of knowing exactly what each squeeze of the tool does. That’s the magic of grasping the inner workings of a riveting tool.

We’ll unravel the mystery step by step, ensuring you grasp every detail without needing a technical background. By the end, you’ll have a clear picture and perhaps even feel inspired to tackle that project you’ve been putting off. Ready to dive in and unleash your inner expert? Let’s get started!

Credit: tameson.com

Basics Of Riveting Tools

Riveting tools are essential in many industries, transforming simple sheets of metal into sturdy structures. These tools offer a reliable way to join materials without welding. If you’re curious about how these tools work, you’re in the right place. Understanding their basics can open up possibilities for various projects and applications.

Types Of Riveting Tools

Riveting tools come in different forms, each suited for specific tasks. Hand riveters are perfect for small projects at home or in the workshop. They’re easy to use and don’t require much strength.

Air-powered riveters, on the other hand, are great for larger industrial tasks. They save time and effort, making them ideal for repetitive jobs. Battery-powered riveters offer mobility, allowing you to work in areas where power sources are limited.

Choosing the right riveting tool depends on your needs and project scale. Have you ever wondered which type would suit your project best?

Common Applications

Riveting tools are used in various sectors, from aerospace to automotive industries. They are crucial in constructing aircraft, ensuring parts stay securely fastened during flight. Automotive manufacturers rely on riveting tools for assembling car components, providing strength and durability.

In home improvement, these tools can be used for assembling furniture or fixing gutters. Imagine being able to repair your own metal fixtures with ease. Riveting tools make it possible. They provide a simple yet effective solution for joining materials.

Where could you see yourself using a riveting tool in your daily life?

Credit: www.huyett.com

Components Of A Riveting Tool

Understanding the components of a riveting tool can transform your DIY projects from simple tasks to masterpieces. Imagine the satisfaction of knowing exactly what each part of your tool does and how it contributes to the riveting process. Let’s break it down and see how you can leverage each component to your advantage.

Handle And Grip

The handle and grip of a riveting tool are like the steering wheel of a car. It’s where you exert control and ensure precision. A good grip provides comfort and reduces fatigue during extended use, so look for rubberized or ergonomically designed handles.

Think about the time you struggled with a tool that didn’t fit well in your hand. A well-designed handle ensures you never face that frustration again. The grip plays a crucial role in maintaining stability, especially when you’re working on a project that demands accuracy.

Nosepiece And Mandrel

The nosepiece and mandrel are the heart of the riveting tool. The nosepiece holds the rivet in place, while the mandrel pulls through to form a secure bond. Choosing the right size nosepiece for your rivet ensures a snug fit, preventing any wobble or misalignment.

Imagine trying to fit a square peg in a round hole; that’s what happens with the wrong nosepiece size. The mandrel, on the other hand, is like the engine, doing the heavy lifting. It’s crucial to check for wear and tear on the mandrel to maintain tool efficiency.

Trigger Mechanism

The trigger mechanism is your go-to for releasing power at the right moment. It’s what makes the rivet snap into place with a satisfying click. A smooth, responsive trigger ensures you don’t have to apply excessive force, making the process seamless.

Have you ever been caught off guard by a stiff trigger that needed too much pressure? A well-maintained trigger mechanism avoids those surprises. Regular lubrication can keep the trigger functioning smoothly and extend the lifespan of your tool.

Understanding each component of your riveting tool not only enhances your work but also prolongs the tool’s life. Which component do you think makes the most difference in your projects?

Functionality Of Riveting Tools

Understanding how riveting tools work helps in knowing their functionality. These tools join materials like metal and plastic. They are crucial in construction, automotive, and other industries.

Principle Of Operation

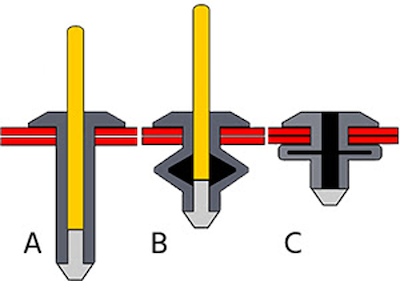

Riveting tools use a simple mechanism. They insert rivets into holes. Rivets are small metal pins. The tool presses the rivet, securing it in place. The rivet expands, locking materials together.

The tool’s design is straightforward. It uses pressure to deform the rivet. This deformation makes the rivet hold tightly. The tool’s handle is squeezed, applying force. The rivet’s head flares out, creating a strong bond.

Force And Pressure Dynamics

Force is key in riveting. The tool generates force through manual or pneumatic means. Manual tools rely on hand strength. Pneumatic tools use air pressure. This pressure ensures the rivet holds firmly.

Pressure dynamics involve converting force into motion. The tool’s components work together to create this motion. This motion drives the rivet into the material. The pressure ensures the rivet expands properly.

Riveting tools balance force and pressure. This balance is vital for secure attachments. Proper pressure avoids damaging the materials. It ensures the rivet deforms correctly for a lasting bond.

Credit: huckaerobolt.com.au

Using A Riveting Tool

Riveting tools join materials using metal fasteners called rivets. These tools press rivets into pre-drilled holes. As pressure is applied, the rivet expands and secures the materials together. Ideal for projects requiring strong, durable bonds.

Using a riveting tool might seem daunting at first, but with the right guidance, it becomes a straightforward and rewarding task. Whether you’re working on a DIY project or a professional job, understanding how to use this tool can make your work more efficient and secure. Let’s dive into the nitty-gritty of using a riveting tool, ensuring you’re well-prepared and safe.Preparation And Setup

Before you begin, gather all necessary materials. You’ll need rivets, the riveting tool, and the two materials you wish to join. Make sure your work area is clean and organized to avoid losing small parts. Choose the right size and type of rivet for your project. This depends on the materials’ thickness and the strength required. Read the riveting tool’s manual to understand how to change and adjust the tool’s nosepieces for different rivet sizes. Insert the correct nosepiece into the riveting tool. This is crucial for securing the rivet properly. Adjust the tool’s settings as per the manual’s instructions to match your rivet type.Step-by-step Operation

To begin, align the materials you intend to join. Drill a hole through both pieces, ensuring it’s slightly larger than the rivet’s diameter. Insert the rivet through the hole. The rivet’s head should be on the visible side of your project. Attach the riveting tool’s nosepiece to the rivet’s mandrel. Squeeze the tool’s handles together firmly. This action pulls the mandrel through the rivet, expanding its end and securing the materials together. When done, the mandrel will snap off. Check your work. The rivet should be flush with the surface, and the materials should be tightly joined. If not, you might need to adjust your technique or tool settings.Safety Precautions

Always wear safety glasses when using a riveting tool. The mandrel can snap off with force, posing a risk to your eyes. Keep your fingers and other body parts away from the tool’s moving parts. It’s easy to get pinched if you’re not careful. Ensure your workspace is well-lit and free of distractions. A focused mind reduces the risk of accidents. Are there other tips or experiences you’d like to share when using a riveting tool? Engaging with fellow DIY enthusiasts can provide new insights and improve your skills.Maintenance And Care

Maintaining your riveting tool ensures its optimal performance and longevity. Regular care prevents unexpected breakdowns. It also keeps the tool functioning smoothly. This section explores cleaning, troubleshooting, and longevity tips.

Cleaning Procedures

Clean your riveting tool after each use. Wipe the exterior with a soft, dry cloth. Use compressed air to remove dust and debris from crevices. Avoid water exposure to prevent rust. Apply a light oil coating to moving parts. This helps reduce friction and wear.

Troubleshooting Common Issues

Facing issues with your riveting tool? Check for loose parts first. Tighten any nuts or screws. Ensure the tool is properly lubricated. Listen for unusual sounds during operation. This can signal a problem. Replace worn-out components promptly. This keeps the tool efficient.

Longevity Tips

Store your tool in a cool, dry place. Avoid extreme temperatures. Regularly inspect the tool for damage. Replace damaged parts immediately. Use the tool for its intended purpose only. Overloading can cause permanent damage. Follow the manufacturer’s guidelines for best results.

Innovations In Riveting Technology

Riveting tools have evolved tremendously over the years. Modern advancements make riveting faster and more precise. Innovations in riveting technology have transformed how industries approach fastening tasks. From construction to manufacturing, new riveting methods enhance efficiency and safety.

Advancements In Design

Design improvements have streamlined riveting tools. Lightweight materials reduce user fatigue. Ergonomic grips offer better control. Enhanced designs minimize noise and vibration. These features ensure smoother operation. Improved designs cater to various applications. They are adaptable to different materials and sizes.

Smart Riveting Tools

Smart riveting tools are gaining popularity. They incorporate advanced technology like sensors. These tools monitor pressure and alignment. Automated systems adjust settings for optimal performance. Connectivity features allow remote monitoring. Data collection aids in predictive maintenance. Smart tools enhance productivity and reduce errors.

Frequently Asked Questions

How Do You Work A Rivet Tool?

Insert the rivet into the hole. Squeeze the rivet tool handles together until the rivet snaps. Remove the tool.

How Does A Rivet Setting Tool Work?

A rivet setting tool clamps and compresses rivets, securing materials together. Insert the rivet, apply pressure, and release. The tool’s handles create leverage, deforming the rivet’s end. This forms a tight bond, ensuring stability. It’s efficient for fastening metal, plastic, or leather.

Suitable for DIY and professional projects.

Do You Have To Drill A Hole Before Using A Rivet Gun?

Yes, you need to drill a hole before using a rivet gun. The hole allows the rivet to secure materials together effectively. Ensure the hole matches the rivet size for proper installation. Drilling ensures the rivet fits snugly and holds components firmly in place.

Always use appropriate drill bits for accuracy.

How Does Riveting Work?

Riveting joins materials using metal fasteners called rivets. A rivet is inserted into pre-drilled holes. The tail end is then deformed to hold materials together. This creates a permanent, strong bond without welding or adhesives. Riveting is commonly used in construction, aviation, and manufacturing for its durability and reliability.

Conclusion

Riveting tools make fastening pieces together simple and efficient. They provide a strong bond without needing welding or screws. Easy to use, these tools are essential in many industries. From construction to crafting, they help secure materials with ease. Understanding their function is key for effective use.

Practice makes perfect. With time, using a riveting tool becomes second nature. Always ensure proper safety measures when operating tools. The right technique ensures a secure and lasting connection. Happy riveting!